About Us

Solution Based Designers and Manufacturers of Continuous Flow Manufacturing Systems

Individual Component Integration

Complete System Design and Manufacturing

Pack N Tec is dedicated to serving and manufacturing the highest quality packaging equipment for international growers, food production facilities, and contract and consumer product manufacturers. Our goal is to manufacture the highest quality equipment for our customers to achieve the highest value for their equipment costs. Learn more at our Youtube Channel.

- Based in Sacramento California

- 20 years in the Packaging Equipment Business

- Factory Direct Manufacturer

- Exceptional Cost Savings

- Highest Quality Food Grade Equipment

- Quick Turnaround – typically 60 days

- Service and maintenance technicians on call throughout Western US

Our Mission

To provide our customers with the most economical, reliable and highest quality packing and processing equipment.

Our Vision

To provide our customers with the highest level of value for custom designed equipment that meets or exceeds their requirements.

Food Safety

Pack N Tec is dedicated to assisting our clients in assessing food safety requirements for any of their current or future equipment needs. We have a highly qualified engineering staff that is very well versed on the current equipment standards within the food processing industries.

Our Value Proposition

- Pricing includes all installation and commissioning

- 1 Year Warranty

- 24/7 Technical Support and Maintenance

- On Call Customer Service

- Spare parts inventory

- Onsite training for all designated personnel

- Detailed operating manual provided

- Customer References

Our Process

We have a four step process that takes our customers initial ideas to finalized custom equipment. Our process assists in development of a concept, creating potential designs, finalizing all mechanical drawings and the manufacturing of their custom equipment.

Client Engagement-Situation Analysis

We utilize the Kepner Tregoe methodology in conjunction with customer driven data to provide definitive equipment solutions. Our initial meetings and follow up discussions will result in an agreed upon plan to evaluate multiple options for potential conceptual ideas that will provide solutions to packaging and equipment requirements.

Conceptual Designs

Our action plan from our initial client meeting will be for PacknTec to provide the client with multiple simple line art drawings of potential equipment requirements that were agreed upon. This set of drawings will lead to client determining and finalizing one or more of the concepts that we will then produce AutoCad and complete mechanical drawings for them to sign off on.

AutoCad and Mechanical Drawings

Client will be provided with AutoCad and mechanical drawings which they then will have the opportunity to evaluate all the material specifications, dimensions, run rates, etc. They will be able to make any appropriate changes as required. With client final approval and sign off, we will begin manufacturing.

Manufacturing Process

Client will be provided with production schedule and will have the opportunity to visit our plant and view their equipment being manufactured at any stage. We can also provide live video as required. We will have benchmarked production goals. There will be quality inspection reports that will be provided throughout the entire manufacturing process. Equipment will be shipped to customer and it will be predetermined as to install requirements.

Solution Portfolio

Filling Machine

Fulfill any filling requirement.

Carton Taping

Click the picture to watch the video.

Feeding Conveyor With Gate Open

Click the picture to watch the video.

Label Applicator

Click the picture to watch the video.

Automated Filling Machine

Click the picture to watch the video.

Pre-made Bag Filling Machine

Click the picture to watch the video.

Pallet Loader

Click the picture to watch the video.

Sorting Equipment

Click the picture to watch the video.

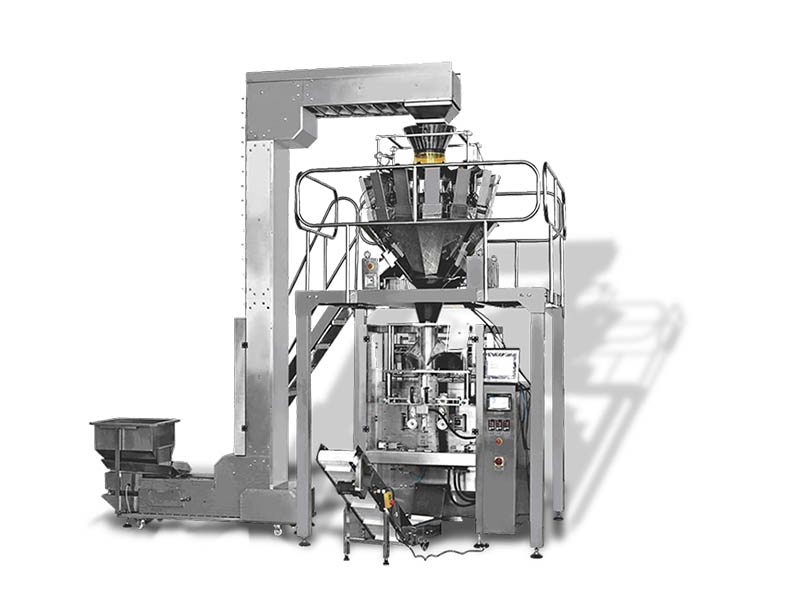

Multihead Weighing System

Click the picture to watch the video.

Conveyor System

Click the picture to watch the video.

Carton Erector

Click the picture to watch the video.

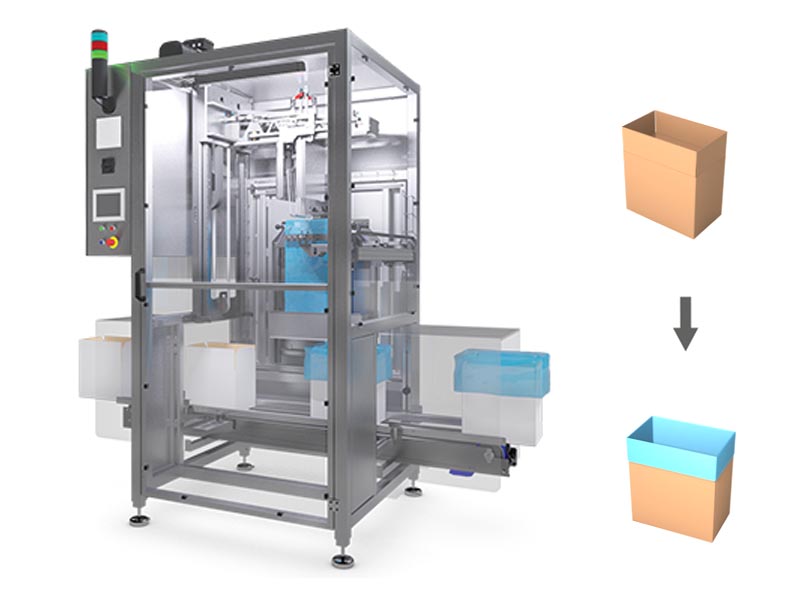

Carton Liner Inserter

Click the picture to watch the video.

Robotic Palletizer

Click the picture to watch the video.

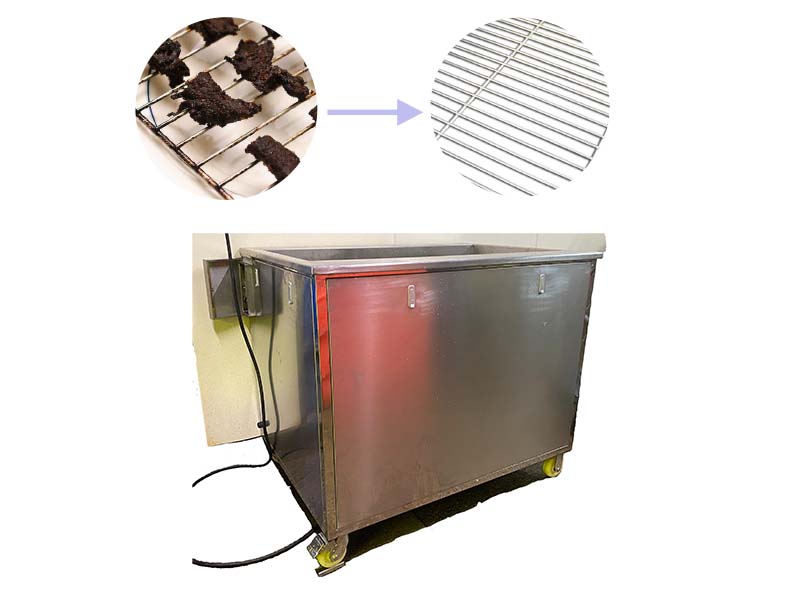

Ultrasound Washer

Click the picture to watch the video.

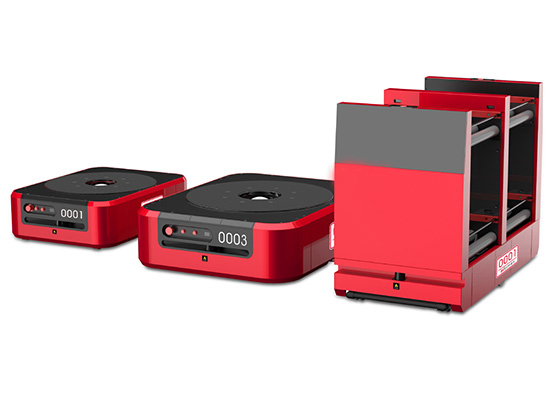

Automated Guided Vehicle

Click the picture to watch the video.

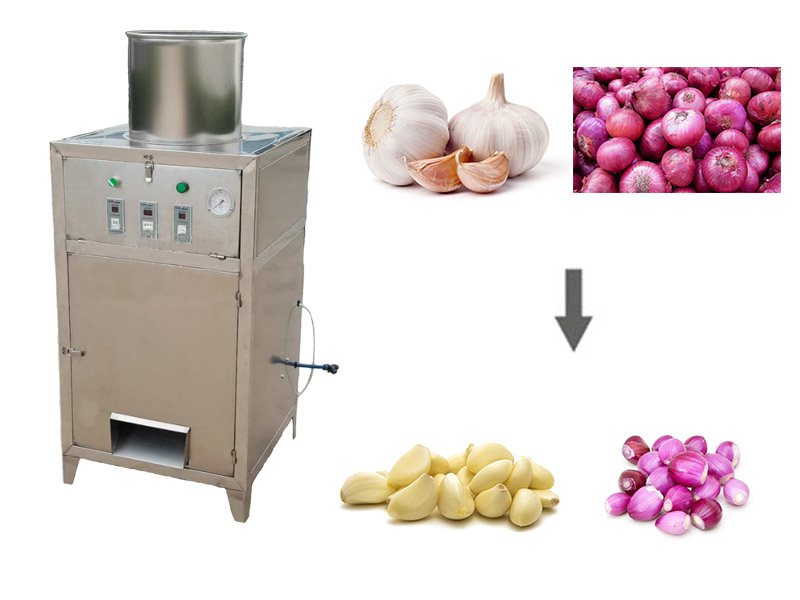

Garlic/Onion Peeler

Click the picture to watch the video.

Produce Chopper

Click the picture to watch the video.

Produce Washer/Dryer

Click the picture to watch the video.

Coffee Bagger and Weigher Solution

Click the picture to watch the video.

Metal Detector and Check Weigher

Click the picture to watch the video.

Shrink Wrapper for Food & Produce

Click the picture to watch the video.

SERVICES

Our friendly, experienced field service specialists will help keep your equipment in top condition. We use the latest diagnostic technology to provide high-quality service and quick turnaround. We also offer customized preventative maintenance programs to fit your needs. It's the convenient way to keep your equipment healthy. From simple preventative maintenance to complex machine upgrades, we’ve got you covered. We know what we’re doing, and we’re dedicated to keeping your equipment up and running. Your satisfaction is our highest priority!

Contact Us

Our Engineering and Sales staffs bring many years of experience and background in designing and manufacturing complex and multifaceted technical equipment. Please let us know how we can help!

Our service team is available and on call 24/7 to handle any service issues.

Address

Sacramento, CA 95838, USAPhone Number

Toll Free 888 232 8566